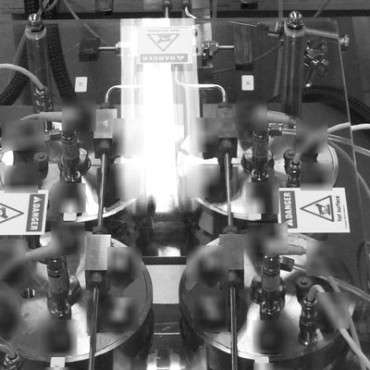

AVESTIN is a manufacturer of high pressure homogenizers of the highest quality Instruments for volumes from 7ml batches up to production capacities are available. Some models allow the unique combination of high pressure homogenization with continuous filtration/extrusions.

Homogenization pressure up to 30,000psi/207 MPa can be achieved.

All EmulsiFlex™ instruments are SIP-sterilisable and autoclavable.

Caracteristics of Avestin Emulsiflex system:

High efficiency:

The homogenising pressure is adjustable between 500 and 30,000 psi. This wide pressure range means that many materials can be processed efficiently in a single pass. This provides the capability of scaling up to an integrated continuous process.

Constant flow

The C3 homogeniser is powered by an electric motor with a constant flow capacity of 3.0L/hr. The flow rate is independent of pressure. Samples as small as 10ml can be processed.

Temperature control:

Inlet and outlet temperatures can be controlled by optional heat exchangers.

Uniform size:

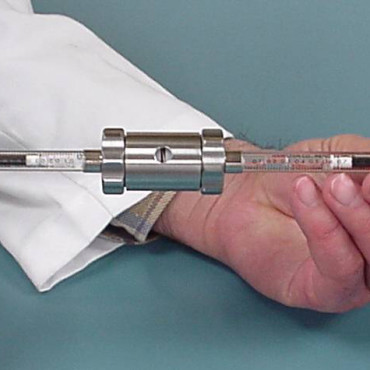

The dynamic homogenising valve maintains a constant pressure. This design produces extremely uniform micro emulsions, with narrow nano – particle size distribution. Emulsiflex systems can also be used as extruders using membranes of specific pore size.

Easy cleaning:

There are no “O” rings or gaskets in the entire product path, which means little or no cross contamination. A wide range of cleaning agents can be flushed through for quick cleaning. The system is steam in place (SIP) sterilisable, and suitable for clean room and GMP manufacturing.

For more details, please visit: Avestin